Para-aramid Filament for Aerospace Engineering: A Game-Changer in High-Performance Materials

In the fast-evolving world of aerospace engineering, innovation in materials plays a pivotal role in advancing technology, ensuring safety, and optimizing performance. Among the many advancements, para-aramid filament for aerospace engineering stands out as a breakthrough material, widely recognized for its exceptional strength, thermal resistance, and lightweight properties. This high-performance synthetic fiber has revolutionized the way aerospace components are designed and manufactured, offering unprecedented capabilities for withstanding extreme conditions.

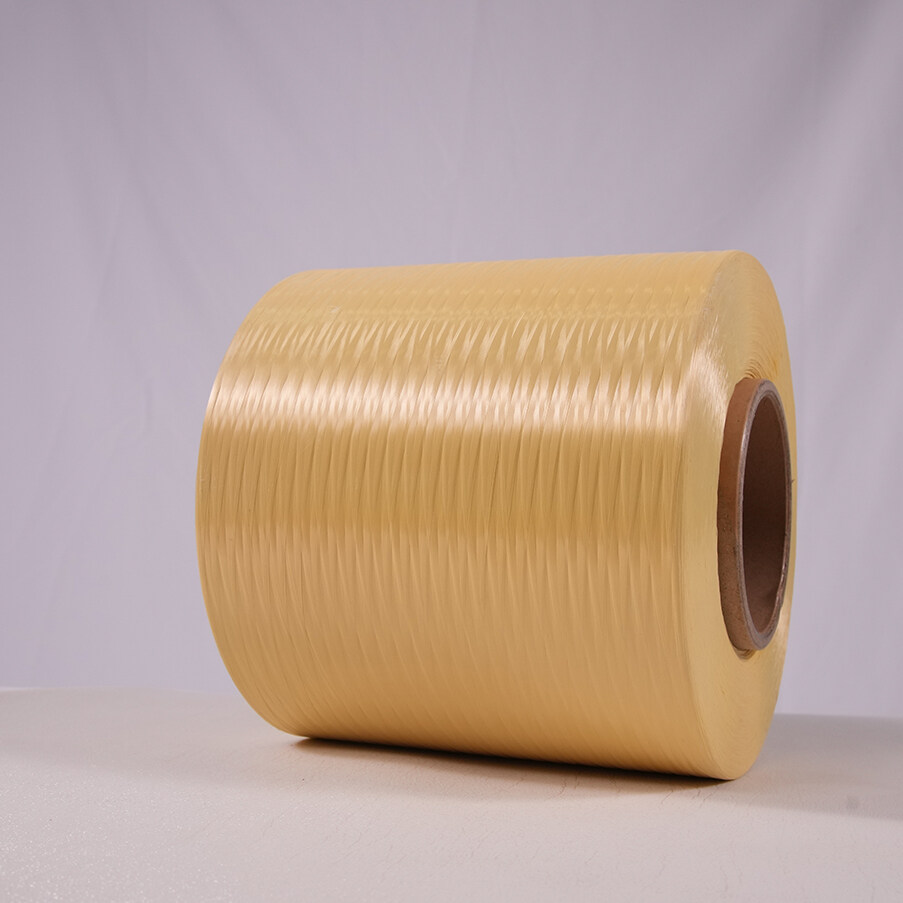

Understanding Para-aramid Filament

To truly appreciate the impact of para-aramid filament in aerospace engineering, it’s essential to first understand what it is and how it works. Para-aramid filament is a type of synthetic fiber known for its outstanding tensile strength, high durability, and resistance to heat and wear. It’s part of the aramid family, which includes both para- and meta-aramids, but para-aramid fibers are distinct in their ability to endure significant stress without losing their structural integrity.

Since their inception in the 1960s, para-aramid fibers have been used in a variety of high-performance applications, but their relevance to aerospace engineering has grown significantly in recent decades.

The Key Properties of Para-aramid Filament

1. High Tensile Strength

One of the defining characteristics of para-aramid filament is its high tensile strength. When compared to steel, pound-for-pound, para-aramid fibers are five times stronger, making them ideal for applications that require lightweight yet strong materials. This is crucial in aerospace engineering, where every gram of weight matters and components must endure high stress during flight.

2. Thermal and Chemical Resistance

Aerospace materials must be able to withstand extreme temperatures, especially during high-speed flight or re-entry from space. Para-aramid filament’s ability to resist temperatures up to 500°C (932°F) without losing strength is one of the reasons it’s favored in aerospace engineering. In addition to thermal resistance, it also resists degradation by most chemicals, further enhancing its suitability for the demanding aerospace environment.

3. Lightweight and Flexible

Weight reduction is a primary concern in aerospace engineering, as it directly impacts fuel efficiency and overall performance. Para-aramid filament offers an excellent strength-to-weight ratio, allowing aerospace engineers to create lighter components without sacrificing durability. Furthermore, its flexibility enables it to be woven into various forms, including composites and fabrics, making it versatile for different aerospace applications.

Para-aramid Filament for Aerospace Engineering: Applications

The usage of para-aramid filament for aerospace engineering spans a wide range of applications, from the reinforcement of composite materials to the manufacture of critical safety equipment. Below are some key areas where para-aramid filament has made a significant impact:

1. Composite Reinforcements

In aerospace engineering, composite materials are commonly used to reduce weight while maintaining structural integrity. Para-aramid filament is frequently used as reinforcement in these composites, particularly in applications requiring high impact resistance. These materials are commonly found in aircraft fuselages, wings, and other structural components that must endure high stress and vibrations during flight.

2. Protective Gear

Para-aramid filament is also widely used in the development of protective gear for astronauts and aerospace engineers. Its resistance to heat and fire, combined with its lightweight nature, makes it an ideal choice for helmets, gloves, and body armor that need to protect individuals from extreme conditions in space or during high-speed flights.

3. Rope and Cables

Aerospace systems often require high-strength, lightweight cables for various applications, including in landing gear, parachute systems, and space exploration devices. Para-aramid filament is a common material in the production of ropes and cables used in these systems, providing the necessary strength without the added weight.

4. Dope Dyed Para-aramid Filament for Aerospace Applications

In certain specialized aerospace applications, the dope dyed para-aramid filament is used to achieve specific color-coding or aesthetic requirements while retaining all the essential mechanical properties. The dope-dyeing process integrates color during the production of the filament, offering enhanced durability compared to traditional dyeing methods.

Advantages of Para-aramid Filament in Aerospace Engineering

1. Enhanced Durability and Longevity

The durability of para-aramid filament significantly extends the lifespan of aerospace components. Whether used in structural reinforcements or protective equipment, the filament’s resistance to environmental stressors—such as UV radiation, extreme temperatures, and chemical exposure—means that it can retain its properties over time, reducing the need for frequent replacements.

2. Improved Safety

Safety is a paramount concern in aerospace engineering. The superior strength and heat resistance of para-aramid filament play a critical role in enhancing the safety of both aerospace components and personnel. For instance, the use of para-aramid fibers in fireproof clothing and heat shields has directly contributed to the protection of astronauts and engineers operating in extreme environments.

3. Fuel Efficiency and Performance Optimization

By reducing the overall weight of aircraft and spacecraft components, para-aramid filament contributes to better fuel efficiency and improved performance. This is especially important in long-duration flights or space missions, where every kilogram saved can translate into significant cost savings and enhanced mission success rates.

Challenges and Considerations

While para-aramid filament offers numerous advantages, there are challenges to consider when incorporating it into aerospace engineering.

1. Cost

The production of para-aramid filament is more expensive than many conventional materials, and this cost is reflected in the price of aerospace components that utilize the fiber. However, the long-term benefits in terms of durability and performance often justify the initial investment, particularly in critical applications where failure is not an option.

2. Moisture Sensitivity

Para-aramid filaments can absorb moisture, which may affect their performance in certain conditions. While this is not a significant issue in the dry environments of space, it can be a factor to consider in humid or wet climates. Engineers often use protective coatings or integrate the filament into moisture-resistant composites to mitigate this effect.

Future Trends and Innovations

As aerospace technology continues to evolve, so too does the development of para-aramid filament and its applications. One area of interest is the integration of smart materials with para-aramid filament to create intelligent composites capable of responding to environmental changes in real-time. This could lead to aerospace components that can self-repair or adapt to different conditions, further improving safety and efficiency.

Another trend is the continued refinement of the manufacturing process for para-aramid filament. Advances in nanotechnology and fiber spinning techniques may result in even stronger, lighter filaments that push the boundaries of what’s possible in aerospace engineering.

Conclusion: The Future of Para-aramid Filament in Aerospace

The use of para-aramid filament for aerospace engineering represents a significant advancement in the field of high-performance materials. Its unmatched strength, lightweight properties, and resistance to extreme conditions make it indispensable in the development of aerospace components that are safer, more efficient, and longer-lasting. As the aerospace industry continues to push the limits of innovation, para-aramid filament will undoubtedly play an increasingly critical role in the future of aviation and space exploration.

With ongoing research and technological advancements, the possibilities for para-aramid filament in aerospace applications are vast. Whether in next-generation aircraft, spacecraft, or protective gear for astronauts, this remarkable material is set to shape the future of aerospace engineering for decades to come.